The Bongard “BFC” roll-in retarder-proofers are used to slow down and control proofing of dough pieces over a certain period of time defined by the user. The principle of operation: The dough pieces are stored in the retarder-proofer between 2°C and 4°C to retard proofing. Operating principle The dough pieces are stored in the retarder-proofer (between 2°C and 4°C) to retard proofing (72 hours maximum). Once the control panel has been programmed, the proofer manages the temperature increase on the basis of information previously entered by the user. The Cargill-Bongard facility is one storage tank of propane. At the Bongard facility our only process is corn drying. Our worst case scenario is a broken fill hose or pipe. The tank has check valves, excess flow valves and hand valves.

|

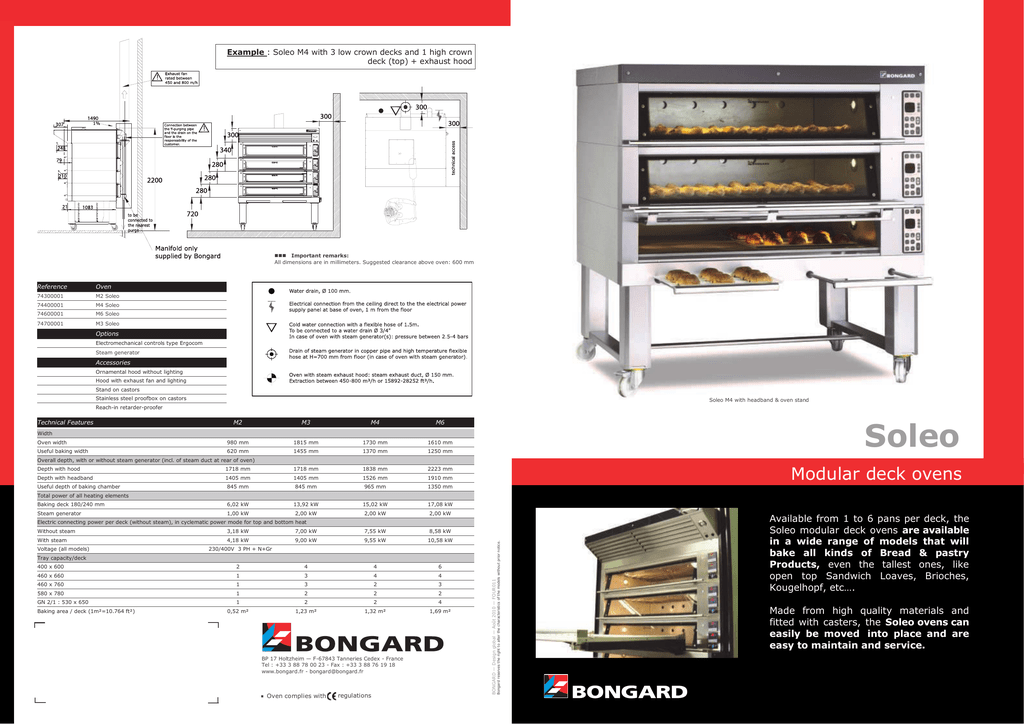

Designed only for the Soleo deck ovens.

- Manual hand-held aluminium loader

“Single” width loader (only) with belt manipulated by one or two operators (without any use of lifter or loader base)

- Full width aluminium loader-unloader for use with integrated lifter

- Modular Deck Oven Operation Manual, October 2011 9 wall for future service, you must also allow 31.5” clearance on the left-hand side as well. Minimum distance between the rear premises wall and the rear part of the oven body (including the damper outlet cover) must exceed 4”.

- Bongard Manual Divider Rounder DB2 The DB2 is a machine for dividing and rounding dough. Number of divisions and dough weights are dependent on the model chosen.

Used with the integrated lifter for Soleo modular oven, it offers the possibility of completely loading and unloading a deck in one single step.

This function can only be used with models adapted to the integrated lifters.

- Aluminium structure

- With the “Full-Width” loader-unloader, the “hooks” will have to be fitted on the integrated lifter

Supplied with belt.

(*) Hand-held loader is supplied with belt unrolling “L” shaped angle iron located underneath the loader, that locks in between concrete hearthplate & backside of oven front.

(xx) Full width loader-unloader is supplied with a belt unrolling rod located above the loader-unloader, that locks into the “hooks”

Data sheet Loader Soleo

Working with flour is like talking to it while trying to guess its whims.

Any baker or confectioner knows the importance of chilling, cooling, deep-freezing, and necessary fermentation of dough. Our fermentation rooms, deep freezers, conservation units and drying cabinets are active participants in your manufacturing process for you to get the best finished product!

Retarder-Proofer

The Bongard “BFC” roll-in retarder-proofers are used to slow down and control proofing of dough pieces over a certain period of time defined by the user.

The principle of operation: The dough pieces are stored in the retarder-proofer between 2°C and 4°C to retard proofing.

Once the control panel has been programmed, the ‘BFC’ automatically manages the changes in temperature based on the settings previously entered by the user.

Characteristics

• Structure made of 60 mm thick isothermal panels

• Product is custom made• Inside lighting

• Can also be set to a warm temperature cycle, up to a maximum of 30°C

• Different sizes of chambers available, depending on models

• Possibility to place retarder proofer chambers side by side

• Delivered without racks

Capacity

• Chambers of 800, 1000 or 1200 mm

• Racks of 400×600 mm, 800×600 mm, 700×900 mm, 750×900 mm and 1215×800 mm can be housed, depending on models

Proofing Cabinets

The Bongard “BFA” and “BFP” proofing cabinets work in the same way than the “BFC” does. They are considered as cabinets and not chambers, meaning that they contain tray slides and not racks. They have a capacity of 20 levels, ranging from 400×600 to 1115×800 mm.

Characteristics

• Large range of models

• Adjustable humidity level (30-90%)

• 3 wheels and 2 adjustable feet on the front make it easy to move

• Can be used as a pastry or a bakery unit, with its U-rails cabinets

Capacity

• 20 levels for tray slides of 400×600 to 1115×800 mm

Proofing Chamber

The “BFE” proofer is used to reach a set temperature (30°C-40°C) very rapidly. It is a chamber that is used for fast proofing of baking and pastry products.

Characteristics

• Made of 60 mm thick isothermal panels

• Custom made product

• Inside lighting

• Can place the chambers side by side

• Delivered without racks

Capacity

• Chambers can contain racks of 400×800, 600×800, 700×900 and 800×1000 mm

• Interior dimension of chambers: 800 mm, 1000 mm or 1200 mm

The “BSP”

The blast freezing ‘BSP’ from ‘Bongard’ is designed to blast chill and blast freeze the product before conservation. The ‘BSP’, with its electromechanical actuator, autonomously controls the temperature and time needed to freeze products. Once this temperature has been reached, it regulates it for 24 hours and automatically switches to storage mode at the end of cycle.

Characteristics

• Fast freezing mode

• Electromechanical control

• Easy to move

• Interior in stainless steel makes for easy cleaning

• Switchable door side

Capacity

• 3 available models of 5, 9 or 15 shelves of 400×600 mm

The “BSC”

The ‘Bongard’ roll-in ‘BSC’ blast freezer is designed to chill and rapidly freeze products before conservation. Its electromechanical control autonomously controls the temperature and time needed to freeze products. The BSC is capable of controlling cold production to reach -18°C as quickly as possible. Depending on the model, 30 kg to 130 kg of raw baguettes can be blast-freezed per hour.

Characteristics

• Buzzer sound indicates the end of the pre-cooling and whole cycle process

• Sheet panels and screws made of stainless steel

• Alternated display of temperature at core and actual time

• Easy cleaning

• Special ventilator for deep freezing

Capacity

• 4 models available

• They can accommodate racks of 400 x 600mm, 600 x 800 mm and 800 x 1000 mm

BLAST CHILLERS

“Speed”, the line of blast chillers from the brand Afinox provides a very fast chilling and freezing. They are modern and ergonomic devices that allow for the recording and downloading of HACCP data through a USB port. Several models of different specifications are available.

Characteristics

• Interior and exterior structure made of stainless steel

• Automatic or manual blast chilling

• Automatic or manual shock freezing

• Thawing, defrosting and optional sterilisation functionalities

The “BSCP”

The Bongard “BSCP” is designed to chill and rapidly freeze products before conservation. With this single equipment, bakers and pastry chefs can chill, freeze and store their products conveniently. Once the desired temperature has been reached, the “BSCP” controls cold production for 24 hours, then automatically switches to conservation mode when the cycle ends. Then it’s just a matter of moving the trays from the blast freezer towards the conservation compartment.

Characteristics

• Dual functionality: blast freezing and conservation mode

• Space saving• Time saving: less time spent handling products

• Buzzer sound indicates the end of cycle

• Manual defrosting for the blast freezer, automatic and/or manual for the conservation unit

Capacity

• Can contain 9 shelves of 400×600 mm

The “BCP”

The “BCP” conservation unit is designed for the conservation of products after blast freezing. After the freezing process, the products are stored in the device at a temperature of -18°C/-22°C.

Characteristics

• Structure made of 80 mm thick isothermal panels, 90 mm thick for the floor

• Comes with an electromechanical control interface (optional electronic control)

Capacity

• Storage capacity of 26 to 146 shelves of 400×600 mm’

The “BTP”

The “BTP” refrigerated workbench from Bongard is designed to store pastry products. Fresh products are kept in a conservation unit that is completely isotherm, with temperatures ranging from 0°C to 10°C on 400×600 mm trays. Ventilated cold maintains an even temperature throughout the cell.

Characteristics

• Regulation done by an electronic thermostat

• Interior and external panels made from stainless steel

• Easy to clean

• Adjustable legs

Capacity

• Workbenches available with 2, 3 or 4 doorsStorage capacity of 8 levels per section, i.e., 16 to 32 shelves of 400×600 mm

Bongard Operation Manual Typewriters

Positive cold

Operating Manual

From the Swiss/German brand Liebherr, we bring you the BKPv 6520. A refrigerator that has been specially designed for the baker’s use, it’s a robust, compact, 600 litre piece of equipment.

Characteristics

• Interior made of chromium-nickel steel

• Digital temperature control system

• Forced air cooling system from de -5° to +15°C

• Body made of stainless or bright steel

• Automatic defrosting using hot gas

• Built according to ISO 9001 :2000 and ISO 14001 standards

• Storage capacity of 20 400×600 mm shelves

• Stainless steel tank with rounded angles and discharge of cleaning water

• High-density insulation of 83mm, with no CFC

• Operational at ambient temperatures, from +10° to +43°C

• Condenser protected by a dismountable dust filter

• Frontal technical access, via a raisable panel

Negative cold

The BGPv 6520 from the Swiss/German brand Liebherr is a 600 litre compact refrigerator that provides negative cold.

Characteristics

• Body made of stainless steel (galvanised rear) or bright steel

• Forced air cooling system from de -35° to -10°C

• Steel interior

• Storage capacity of 400×600 mm, with 20 shelves

• Digital temperature control

• Automatic defrosting using hot gas

• Built according to ISO 9001 :2000 and ISO 14001 standards

• Stainless steel tank with rounded angles and discharge of cleaning water

• High-density insulation of 83mm, with no CFC

• Operational at ambient temperatures, from +10° to +43°C

• Condenser protected by a dismountable dust filter

• Frontal technical access, via a raisable panel